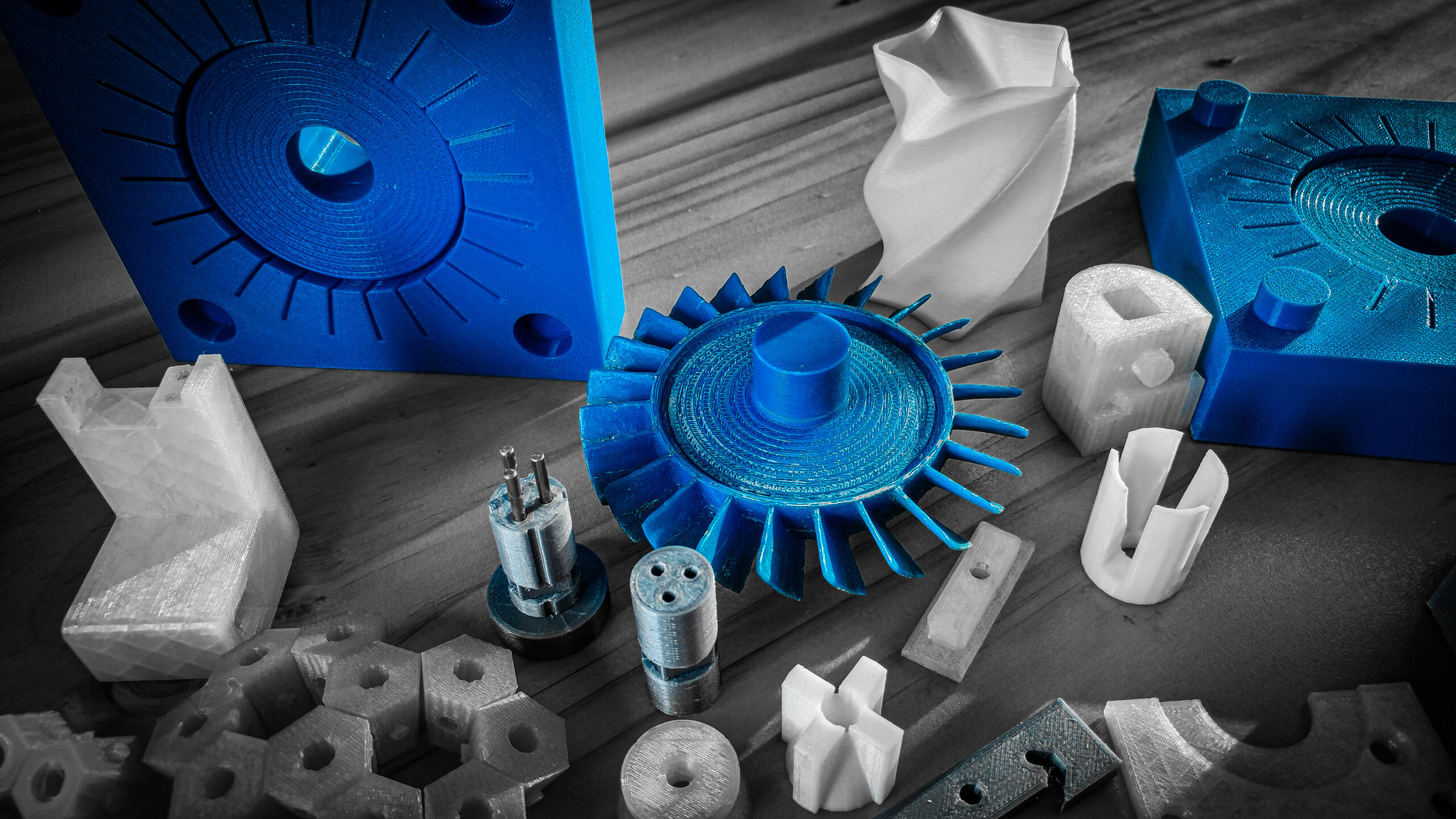

When most people think of 3D printing, they picture plastic filament spooling through a printer to create models, prototypes, and parts. But the world of 3D printing materials has expanded far beyond basic PLA and ABS.

New materials are unlocking stronger, more flexible, and even sustainable possibilities. Here are some of the most exciting innovations shaping the future of 3D printing:

🔹 Metal Filaments & Powders – 3D printing isn’t just for plastic anymore! Metal printing is revolutionizing industries like aerospace and automotive, allowing for lightweight yet durable components made from titanium, aluminum, and stainless steel.

🔹 Carbon Fiber & Composites – Need strength without the weight? Carbon fiber-reinforced filaments offer high durability, making them perfect for drones, sports equipment, and high-performance parts.

🔹 Flexible & Elastic Materials – TPU (thermoplastic polyurethane) and other rubber-like filaments make it possible to print flexible, shock-absorbing designs—think custom phone cases, wearables, or even shoe soles.

🔹 Biodegradable & Recycled Filaments – With sustainability in focus, materials like recycled PETG and biodegradable PLA blends are helping reduce waste while keeping 3D printing eco-friendly.

🔹 Wood, Ceramic, & Concrete Printing – Yes, you read that right! Wood-infused filaments create stunning, natural-looking prints, ceramic printing is enabling custom pottery, and even houses are being 3D printed with concrete!

The materials we use define what’s possible in 3D printing. As these innovations continue, the line between prototyping and full-scale production is disappearing.

At VisionTek3D, I’ve experimented with different materials to push the limits of creativity and functionality. It’s an exciting time to be part of this evolving industry!

What’s the most interesting 3D printing material you’ve worked with (or want to try)? Let’s discuss in the comments!